DfMA offers solutions that reduce building risks and costs. Perhaps the most important thing to understand about DfMA is that it is a trend that parallels and builds upon several other dominant trends in technology and industry: As markets around the world continue to struggle with housing shortages, climate change, and soaring raw material costs, DfMA is positioned to become a dominant trend in the not-too-distant future. We’ll conclude this series with a discussion about where DfMA is going and the factors that will make it an increasingly attractive option for architects and builders going forward. Understanding what worked, what didn’t, and why the company failed are critical to moving DfMA forward in the coming years. Many important lessons can be learned from Katerra’s rapid growth and decline. The company’s assets were later acquired by Volumetric Building Companies (VBC), which plans to produce several different building products in the acquired facilities. Founded in 2015, the startup spent more than $2 billion before going bankrupt in 2021. The rise and fall of Katerra (the most ambitious DfMA startup ever launched) is the most important development in recent DfMA history. In the coming blogs, I’ll discuss each of the following aspects of DfMA, starting with the basics: In this blog series, I will take a deep dive into DfMA to discuss its core elements, the benefits of DfMA, recent developments and setbacks, and the bright future that I think lies ahead for this ultra-efficient approach to construction. And I think the root of the problem has to do with manufacturing, more so than any other aspect of the process. While there have been advances in recent years, the growth and adoption of DfMA has been characterized by some major setbacks. Based on these advantages alone, one might expect DfMA to become the default method of construction worldwide as architects, builders, and owners seek new efficiencies to offset labor shortages and rising material costs - but some concerns haven’t let that happen.

DfMA offers solutions that reduce building risks and costs. Perhaps the most important thing to understand about DfMA is that it is a trend that parallels and builds upon several other dominant trends in technology and industry: As markets around the world continue to struggle with housing shortages, climate change, and soaring raw material costs, DfMA is positioned to become a dominant trend in the not-too-distant future. We’ll conclude this series with a discussion about where DfMA is going and the factors that will make it an increasingly attractive option for architects and builders going forward. Understanding what worked, what didn’t, and why the company failed are critical to moving DfMA forward in the coming years. Many important lessons can be learned from Katerra’s rapid growth and decline. The company’s assets were later acquired by Volumetric Building Companies (VBC), which plans to produce several different building products in the acquired facilities. Founded in 2015, the startup spent more than $2 billion before going bankrupt in 2021. The rise and fall of Katerra (the most ambitious DfMA startup ever launched) is the most important development in recent DfMA history. In the coming blogs, I’ll discuss each of the following aspects of DfMA, starting with the basics: In this blog series, I will take a deep dive into DfMA to discuss its core elements, the benefits of DfMA, recent developments and setbacks, and the bright future that I think lies ahead for this ultra-efficient approach to construction. And I think the root of the problem has to do with manufacturing, more so than any other aspect of the process. While there have been advances in recent years, the growth and adoption of DfMA has been characterized by some major setbacks. Based on these advantages alone, one might expect DfMA to become the default method of construction worldwide as architects, builders, and owners seek new efficiencies to offset labor shortages and rising material costs - but some concerns haven’t let that happen.

This approach offers tremendous benefits.Īs ConstructionDive explains, DfMA enables spaces to be built more quickly at a lower cost while reducing the risk of project delays and minimizing on-site labor requirements.

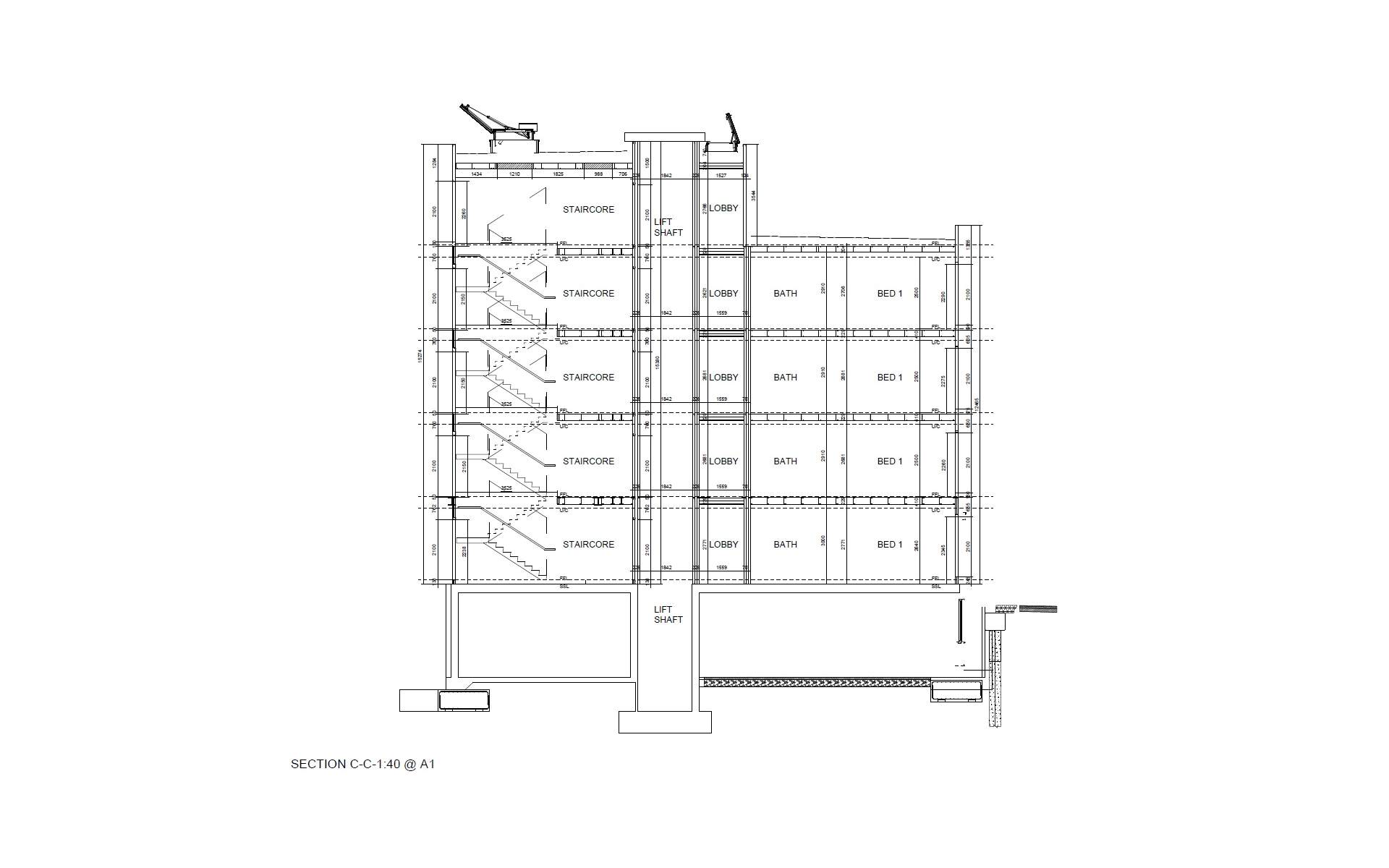

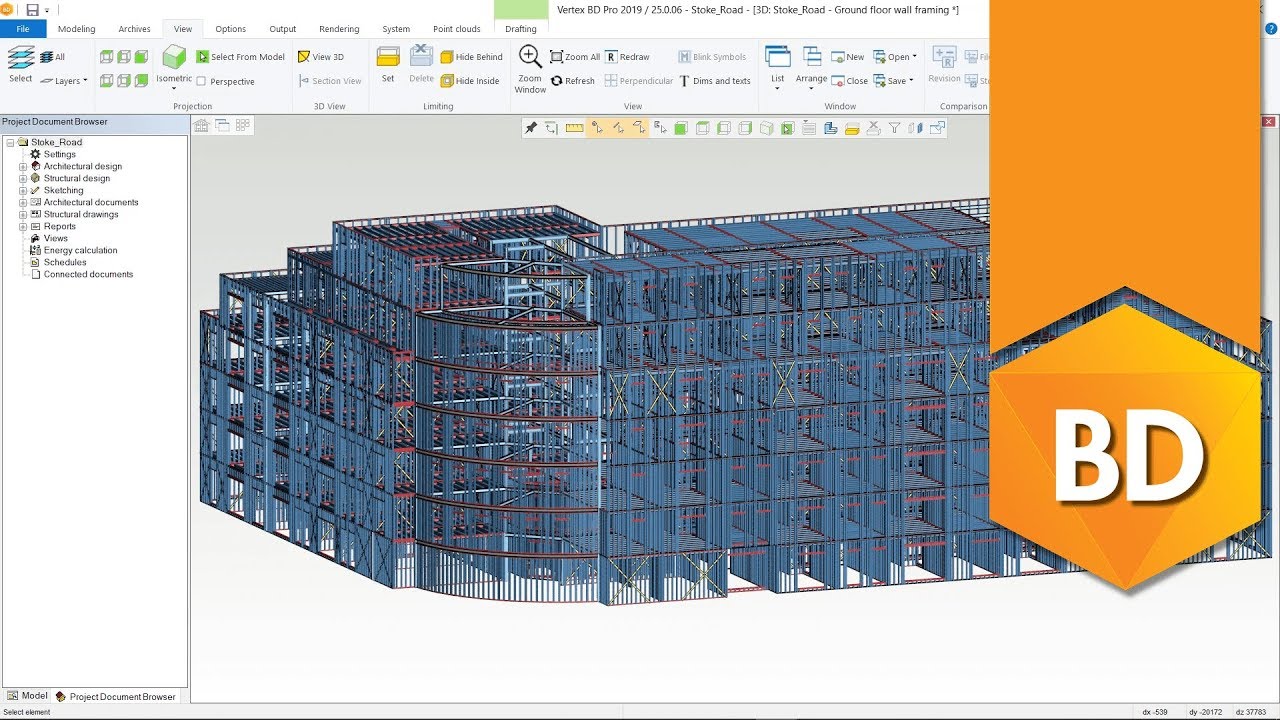

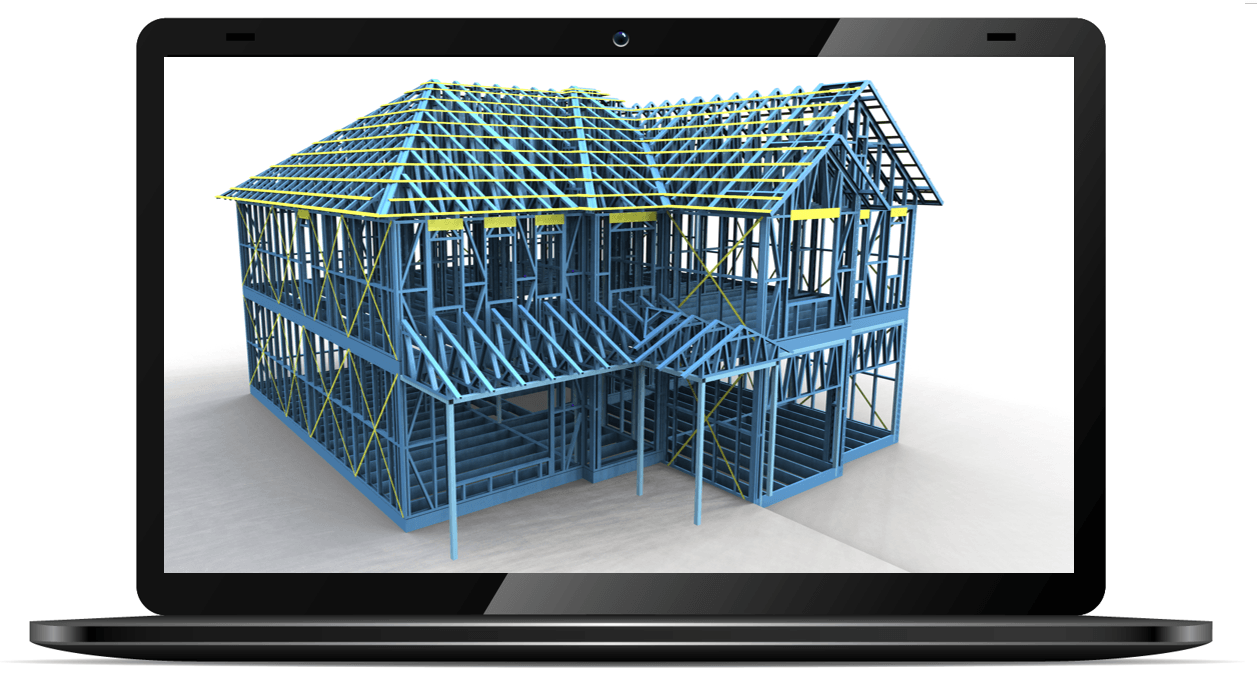

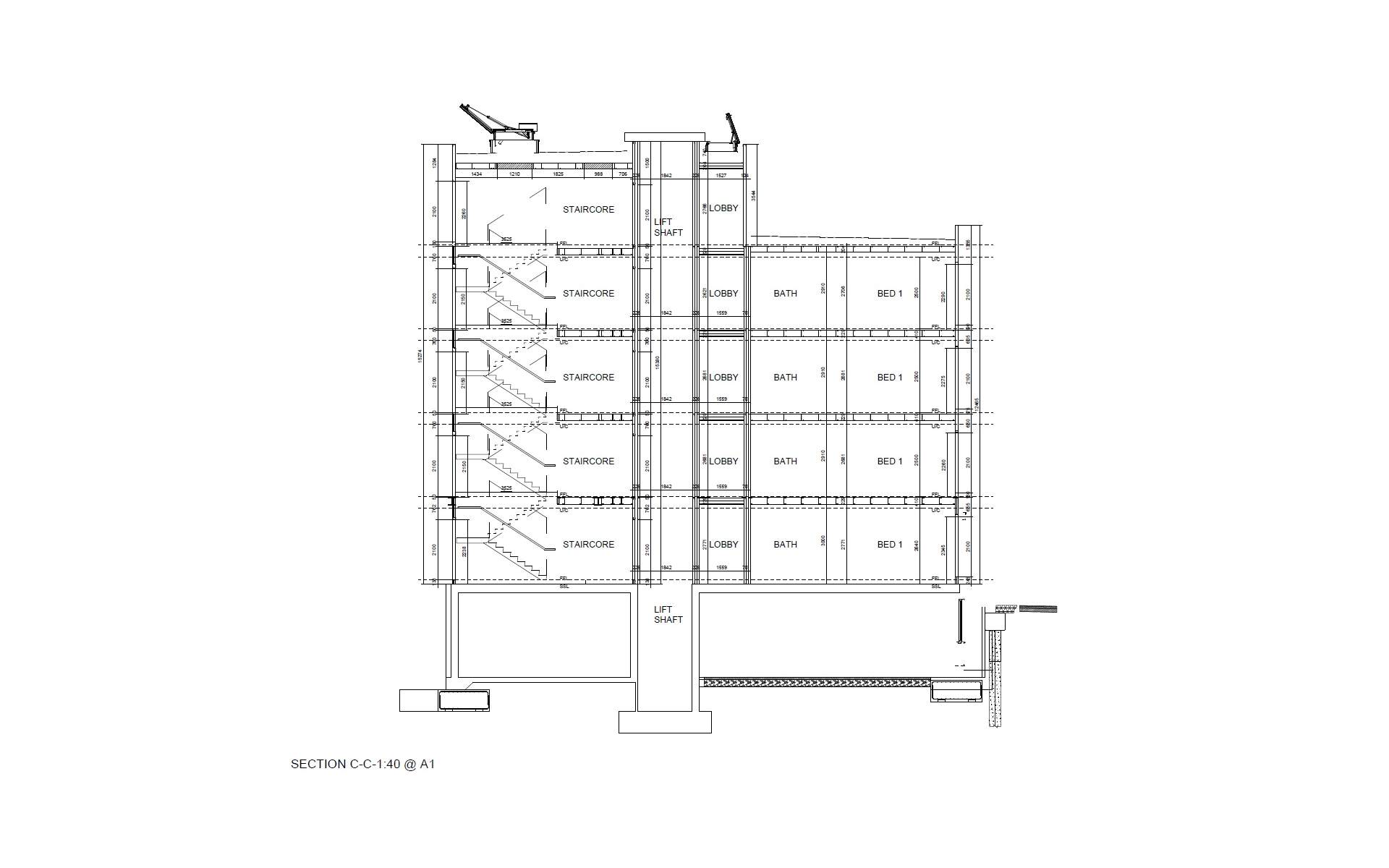

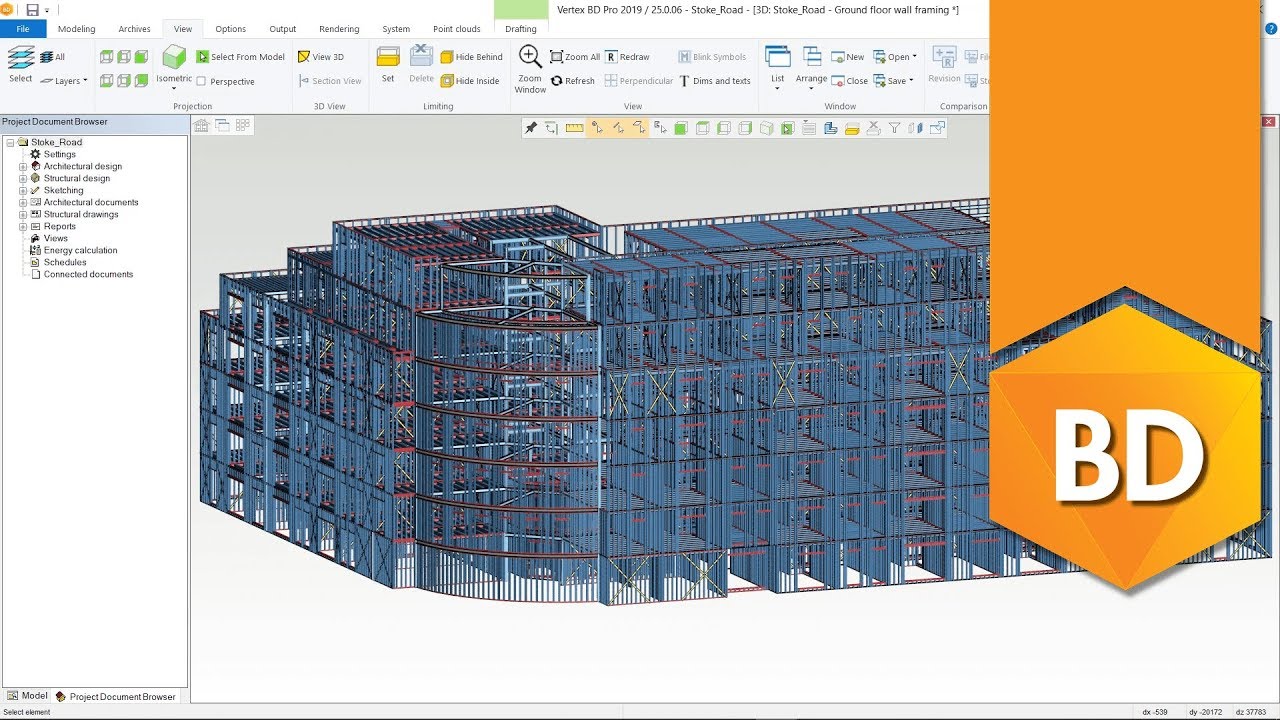

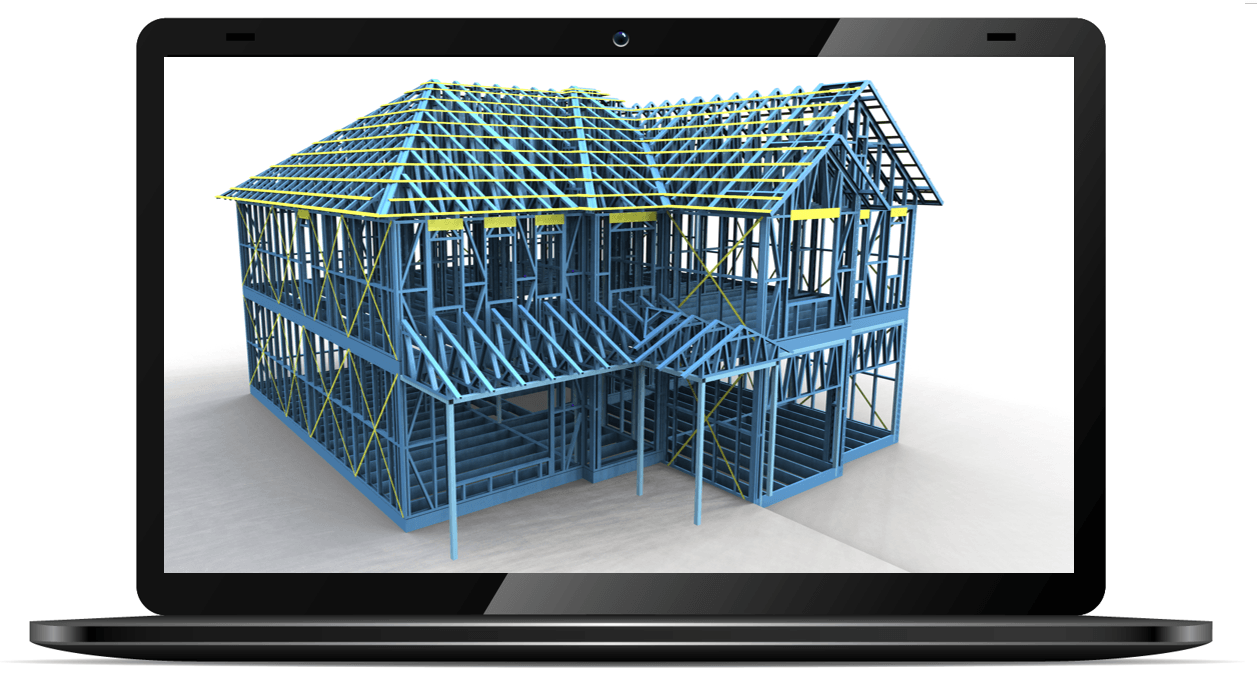

Broadly, DfMA entails designing and manufacturing in a factory all the elements and components of a building, which are later to be assembled on-site. In some circles, that effort is known as design for manufacturing and assembly (DfMA). For decades, architects, engineers, and builders have been looking for ways to introduce the efficiencies of manufacturing into construction.

0 kommentar(er)

0 kommentar(er)